The Shells That Count: What Ukraine Reveals About Western Defense Procurement

Ukraine fires 6,000 artillery rounds daily while Western production struggles to keep pace. The conflict has not proven that mass defeats precision—it has exposed a procurement philosophy built for wars that may never come while neglecting wars that might.

The Shells That Count

Ukraine fires 6,000 artillery rounds per day. Russia fires 20,000. Before February 2022, the United States produced 14,000 rounds per month—barely enough to sustain Ukraine for two days of combat. This arithmetic has reshaped Western defense thinking more than any battle or breakthrough.

The question consuming defense ministries from Washington to Warsaw seems straightforward: does Ukraine prove that mass artillery production defeats precision weapons? The answer, however, is neither simple nor the one that procurement reformers want to hear. What Ukraine actually demonstrates is something more uncomfortable—that Western militaries built force structures for wars they wanted to fight rather than wars they might have to fight, and that correcting this error will require more than budget increases.

The conflict has exposed a fundamental mismatch between Western procurement philosophy and the demands of high-intensity attrition warfare. For three decades, NATO optimized for precision: fewer platforms, exquisite targeting, minimal collateral damage. This made sense for expeditionary operations against technologically inferior adversaries. It makes less sense when your opponent can absorb punishment, jam your guidance systems, and simply outproduce you.

The Precision Paradox

The Gulf War cast a long shadow. When precision-guided munitions obliterated Iraqi forces in 1991, Western military establishments drew a seductive conclusion: technology had transcended industrial capacity. Quality would always defeat quantity. The “Revolution in Military Affairs” became doctrine, budget, and identity.

What followed was predictable. The United States and its allies invested heavily in precision systems while allowing conventional ammunition production to atrophy. By 2022, American 155mm shell production had fallen to 14,000 rounds monthly—a number that sounds adequate until you realize Ukraine’s consumption rates. The EU’s collective output was similarly anemic. Stockpiles accumulated during the Cold War provided a cushion, but cushions compress.

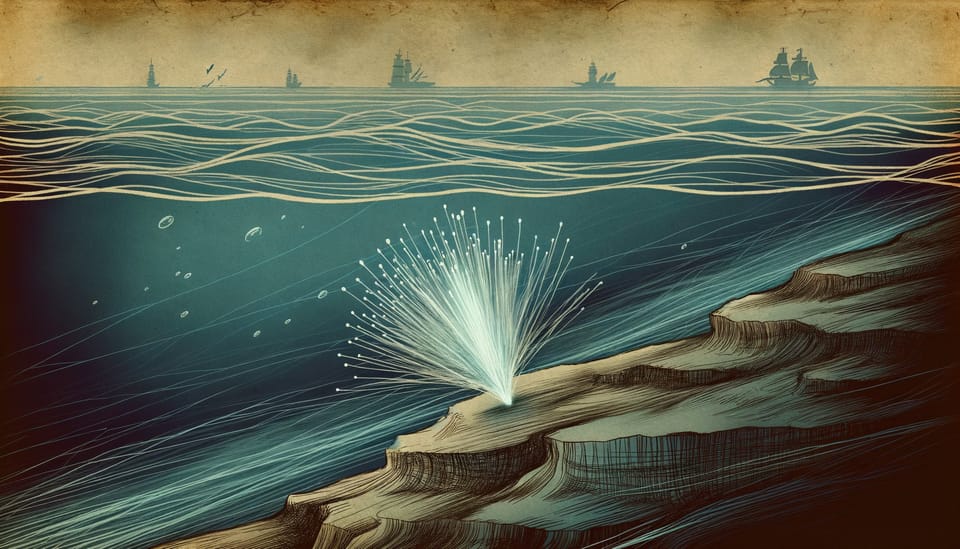

Ukraine revealed the compression. According to analysis from the Royal United Services Institute, Russian artillery “is fixing the Ukrainian military and preventing the Ukrainians from concentrating to undertake offensive manoeuvre” while Russian electronic warfare “is denying Ukraine a sufficiently fast kill chain to destroy Russia’s artillery.” The precision systems that were supposed to provide decisive advantage proved vulnerable to systematic degradation.

Consider the M982 Excalibur, America’s premier precision artillery round. Each shell costs approximately $160,000 and can strike within three meters of its target. In early 2022, Ukrainian forces reported hit rates around 55%—impressive for artillery. By late 2023, Russian electronic warfare had reduced effectiveness to roughly 6%. The shells still worked mechanically. They simply couldn’t find their targets.

This pattern repeated across precision systems. GPS jamming degraded satellite-guided munitions. Sophisticated air defenses forced standoff ranges that reduced accuracy. Electronic countermeasures disrupted the sensor-to-shooter chains that precision warfare requires. The systems weren’t useless—when they worked, they remained devastatingly effective. But they worked less often than doctrine assumed.

The response was inevitable: volume. Ukrainian commanders, unable to rely on precision effects, compensated with mass. If one guided round had a 6% chance of hitting, ten unguided rounds saturating an area might achieve similar results at lower total cost. The calculus was brutal but rational.

Industrial Realities

Western defense establishments have responded with urgency, if not always effectiveness. The U.S. Army has pushed production from 14,000 rounds monthly toward 40,000, with ambitions to reach 100,000 by 2025. The European Union launched its Act in Support of Ammunition Production (ASAP), targeting two million shells annually by end-2025. NATO established new coordination mechanisms. Billions flowed into industrial expansion.

Yet the bottlenecks proved stubborn. Artillery shell production depends on propellant manufacturing, which depends on nitrocellulose production, which depends on cotton linters and specialized chemical processes. Each link in the chain has its own constraints. Defense industry analysis found that expanding output requires not just money but time—years to build facilities, train workers, and qualify production lines.

The numbers tell a story of structural limitation. American production targets, even if achieved, would supply roughly three months of Ukrainian consumption at current rates. European targets face similar constraints. Meanwhile, Russia increased production 200-300% through command economy mobilization, accepting quality degradation in exchange for volume.

This asymmetry compounds monthly. Each quarter of delayed Western production requires additional months to overcome the accumulated deficit. The industrial base that atrophied over three decades cannot reconstitute in three years, regardless of funding.

Some analysts see salvation in drones. Ukrainian forces have pioneered the use of first-person-view (FPV) drones as precision artillery substitutes—cheap, expendable, and devastatingly accurate when they reach their targets. A $500 drone carrying a modified grenade can destroy a $3 million tank. The economics seem compelling.

But military analysts caution against overstating the substitution. Drones excel at certain missions—hunting individual vehicles, striking exposed positions, providing persistent surveillance. They struggle with others—suppressing fortified positions, delivering sustained fires, operating in contested electromagnetic environments. Artillery and drones complement rather than replace each other.

The deeper issue is that drone production faces its own industrial constraints. Ukraine produces thousands monthly but consumes them faster. The supply chains for motors, batteries, cameras, and electronics depend on global manufacturing networks that cannot instantly scale. Drones shift the production challenge rather than eliminating it.

What Ukraine Actually Proves

The temptation to extract simple lessons from Ukraine should be resisted. The conflict does not prove that mass defeats precision, nor that precision remains supreme despite setbacks. It proves something more nuanced and more troubling: that military effectiveness depends on matching capabilities to context, and that Western procurement systems have systematically failed this test.

Three dynamics deserve attention.

First, precision weapons remain extraordinarily effective when their enabling infrastructure survives. HIMARS strikes on Russian ammunition depots, command posts, and logistics nodes produced effects far exceeding their numerical weight. The problem wasn’t precision itself but the assumption that precision would always function as designed. Electronic warfare, air defense, and operational security can all degrade precision systems. Procurement strategies that assume permissive environments will produce forces unprepared for contested ones.

Second, industrial capacity constrains options in ways that operational planning often ignores. Ukrainian commanders would prefer precision effects for every engagement. They cannot have them because production cannot supply them. This forces tactical adaptation—using mass where precision would be preferable, accepting higher casualties to achieve objectives, ceding initiative when ammunition runs low. Industrial limitations become operational constraints become strategic outcomes.

Third, the interaction between precision and mass creates dynamics that neither approach alone can address. Russian forces use massed artillery to fix Ukrainian positions, then employ drones and precision strikes against high-value targets identified by the bombardment. Ukrainian forces use drones to locate Russian artillery, then mass fires to suppress it. Each approach enables the other. Pure precision or pure mass strategies would fail where hybrid approaches succeed.

The implications for Western procurement are uncomfortable. The precision-centric force structures developed since 1991 assumed short, decisive conflicts against technologically inferior adversaries. Ukraine demonstrates that peer conflicts may be long, attritional, and fought in environments where precision advantages erode. Building forces only for the preferred scenario leaves nations unprepared for the probable one.

The Portfolio Problem

Defense procurement is ultimately portfolio management under uncertainty. No nation can afford to optimize for every contingency. Choices must be made about which capabilities to prioritize, which risks to accept, and which scenarios to discount.

Western nations made a bet. They wagered that precision would dominate future warfare, that industrial capacity could be reconstituted if needed, and that conflicts requiring mass would either not occur or could be avoided. Ukraine revealed the bet’s stakes.

The response has been predictable: calls to rebalance toward mass. Increase shell production. Stockpile more ammunition. Rebuild industrial capacity. These prescriptions are correct but incomplete. They address the revealed weakness without considering what new vulnerabilities rebalancing might create.

The European Defence Industrial Strategy illustrates the tension. The €1.5 billion European Defence Industry Programme and €500 million ASAP initiative prioritize ammunition production. Reasonable, given shortages. But every euro spent on shells is a euro not spent on next-generation capabilities—autonomous systems, electronic warfare, cyber operations. The opportunity cost is real even if difficult to quantify.

The United States faces similar choices. The FY2025 defense budget allocates $29.8 billion for munitions, including both conventional ammunition and precision-guided munitions. This represents a significant increase but still forces trade-offs. More shells mean fewer hypersonic missiles, or fewer autonomous platforms, or less investment in production facilities for systems not yet designed.

The honest answer is that no procurement strategy eliminates risk—it only shifts risk between scenarios. A force optimized for attrition warfare may struggle against adversaries who achieve precision effects despite countermeasures. A force optimized for precision may collapse when those systems are degraded. The goal is not perfect preparation but acceptable vulnerability across plausible futures.

Institutional Constraints

Even with unlimited budgets, Western procurement systems would struggle to adapt. The structures built for peacetime acquisition resist wartime urgency.

Contracting timelines stretch years. Environmental reviews add months. Workforce training takes time that compressed schedules cannot compress. The U.S. Defense Production Act provides authorities for emergency mobilization, but exercising those authorities requires navigating bureaucratic processes designed for deliberation rather than speed.

European regulations compound the challenge. REACH chemical registration requirements, labor regulations, and environmental standards all serve legitimate purposes. They also slow production expansion. A propellant facility that meets American standards may require modification for European markets. Supply chains that cross regulatory boundaries face compliance costs that add time and expense.

Multinational coordination adds another layer. NATO’s standardization processes ensure interoperability—shells produced in one country can fire from another country’s guns. But standardization takes time. The NATO Support and Procurement Agency coordinates acquisition across members, yet each nation retains procurement sovereignty. Collective action problems persist despite collective threats.

The institutional challenge is not that bureaucracies are irrational but that they optimize for different objectives than wartime production. Peacetime procurement prioritizes competition, transparency, and accountability. Wartime production prioritizes speed, volume, and flexibility. The same rules that prevent corruption and waste in peacetime become obstacles when urgency demands shortcuts.

Reform is possible but painful. Streamlining acquisition requires accepting risks that peacetime processes exist to mitigate. Expanding production requires investments that may prove unnecessary if conflicts end or evolve. Building industrial surge capacity means maintaining facilities and workforces that operate below efficiency during peace. Each reform trades one value for another.

What Happens Next

The most likely trajectory is muddled incrementalism. Western nations will increase ammunition production without fundamentally restructuring procurement systems. Stockpiles will grow but remain below wartime consumption rates. Precision systems will receive upgrades to counter electronic warfare while mass production expands in parallel. The portfolio will rebalance toward the middle without fully committing to either extreme.

This outcome reflects political reality. Defense budgets compete with domestic priorities. Industrial policy requires sustained commitment that electoral cycles discourage. Bureaucratic reform threatens entrenched interests. The path of least resistance is gradual adjustment rather than transformation.

The risk is that gradual adjustment proves insufficient. If a major conflict erupts before rebalancing completes, Western forces may face the same arithmetic that constrained Ukraine—precision systems degraded, mass production inadequate, stockpiles depleted faster than replenished. The gap between capability and requirement would be filled with casualties.

Alternative trajectories exist but require choices that democratic societies find difficult. Genuine industrial mobilization would redirect resources from consumption to production, accepting economic costs for security benefits. Procurement reform would sacrifice oversight for speed, accepting corruption risks for capability gains. Strategic clarity would mean explicitly preparing for specific adversaries, abandoning the fiction of general-purpose forces.

None of these alternatives is obviously correct. Each involves trade-offs that reasonable people weigh differently. What Ukraine proves is not which choice is right but that the choice cannot be avoided. The precision revolution did not abolish industrial warfare. It merely disguised the continuing relevance of production capacity until a conflict large enough to consume stockpiles revealed the truth.

FAQ: Key Questions Answered

Q: Can drones replace artillery in modern warfare? A: Not entirely. Drones excel at precision strikes against individual targets and persistent surveillance, but they cannot deliver the sustained suppressive fires that artillery provides. Ukrainian forces use both in complementary roles—drones to find targets, artillery to saturate areas, drones again to assess effects. The systems enable each other rather than substituting.

Q: How long would it take Western nations to match Russian artillery production? A: Current trajectories suggest 3-5 years to reach production rates approaching Russian output, assuming sustained investment and no major disruptions. The constraint is not money but physical infrastructure—propellant plants, forging facilities, trained workers—that cannot be created instantly regardless of funding.

Q: Why did precision weapons perform worse than expected in Ukraine? A: Russian electronic warfare systematically degraded GPS and other guidance systems. The M982 Excalibur’s effectiveness reportedly dropped from 55% to 6% as Russian countermeasures improved. Precision weapons require functioning sensor-to-shooter networks; when those networks are contested, precision advantages erode.

Q: What does Ukraine mean for Taiwan contingency planning? A: Taiwan presents different challenges—primarily naval and air rather than ground artillery—but the industrial capacity lesson applies. Any extended conflict will consume munitions faster than peacetime production can replace them. Stockpile depth and production surge capacity matter for Taiwan as they matter for Ukraine.

The Quiet Reckoning

Western defense establishments face a reckoning they have long deferred. The precision revolution promised escape from industrial warfare’s demands—fewer shells, smarter weapons, decisive effects without mass mobilization. Ukraine demonstrated that the promise was conditional. When conditions change, the old arithmetic reasserts itself.

The question is not whether mass artillery defeats precision weapons. Both matter. The question is whether procurement systems designed for one type of warfare can adapt to another before adaptation becomes irrelevant. The shells are counting down, and the factories are only beginning to wake.

Sources & Further Reading

The analysis in this article draws on research and reporting from:

- RUSI Special Report on Ukraine - Detailed assessment of Russian artillery and electronic warfare effectiveness in early conflict phases

- European Defence Industrial Strategy - EU framework for ammunition production expansion and defense industrial coordination

- NATO-Ukraine Strategic Defence Procurement Review - Recommendations for aligning Ukrainian procurement with NATO standards

- U.S. FY2025 Defense Budget - Munitions allocation and investment priorities

- Small Wars Journal: Beyond the Hype - Analysis of drone limitations relative to artillery

- Wassenaar Arrangement Overview - Export control framework affecting dual-use technologies

- Defence Industry EU Analysis - Industrial bottlenecks and production challenges